|

|

|

||||||||||||||||||||||||||||||||||||||

|

|

|

CREASE & LUMP™ DETECTION

TECHNOLOGY

Technology for Innovators, fix the problem!

|

|||||||||||||||||||||||||||||||||||||

|

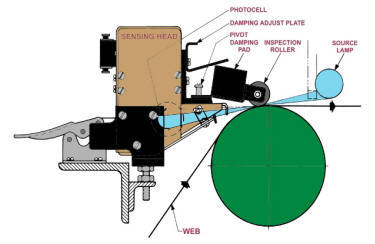

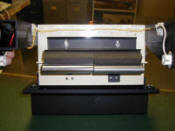

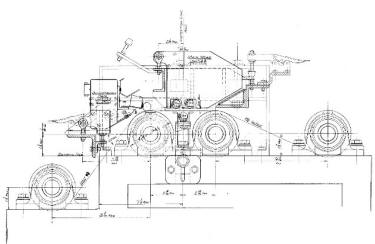

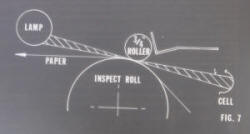

Detect Elevation Defects:Our Crease and Lump™ Detection Technology is designed to detect creases, lumps, splices, and other types of elevation defects in moving webs of material. Because of their mechanical construction and operating principles, these detectors can be used in a wide variety of web inspection applications.

|

|||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

Span Any Web:

Span Any Web:

Our Crease and Lump™ Detection Technology uses modular sensing heads with two three inch long rollers to provide a six inch wide inspection capacity. These sensing heads can be combined, side by side, to span any web width required for your application.

Call SDS:

Call us today to discuss your web inspection applications and to learn more about the industry's most complete line of web inspection related products.

Home | Products | Download Center | History | News | Employment | Contact | Links | Feedback | Corporate Values

Information provided herein protected - © Copyright 2003-2019 Splice Detector Systems

![]()

![]()

Monitor All Materials:

Monitor All Materials: