|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

SUCCESS STORY EUROPE

CASE STUDY

|

|

FCS SHEETER INSPECTION

TECHNOLOGY

Technology for Innovators, fix the problem!

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Maximize Profitability:In today's highly competitive market place, increasing customer demands require comprehensive quality management and control. Sheet fed printing and packaging processes require higher end product of specialty coated and non-coated material that is demanding in terms of quality and delivery.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

Dirt Type Defects |

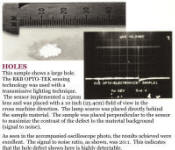

Hole Type Defects |

Coating Scratches |

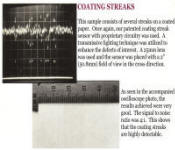

Coating Streaks |

The Model 3600 OPTOMIZER® FCS Sheeter Inspection™ Technology is mounted prior to the cutter in feed. Upon detection of a mission critical defect, a reject gate will be activated momentarily altering the flow of the "BAD" sheets to a reject bin collection system for further customer analysis. This ensures the skids of sheeted stock with value critical defects get stopped at the source before they are delivered to the customer. These quality initiatives will prevent and reduce smash blankets, press downtime, damage sensitive components or coating equipment and delivery delays costing you customers and market position.

100% Inspection Coverage:

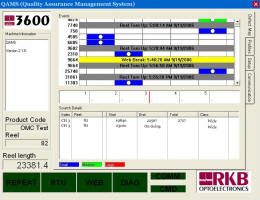

Each Model 3600 OPTOMIZER® FCS Sheeter Inspection™ Technology is designed to span the entire web width for 100 percent inspection of the web material. Now you can guarantee that your products are fully qualified prior to subsequent processing or shipment to customers. Our (QAMS) Quality Assurance Management System Toolpack™ is included with each system to provide complete defect data collection, analysis, reporting, setup, and diagnostic capabilities. From unwind to stacking, your can be assured your product will be defect free.

|

|

|

|

|

|

|

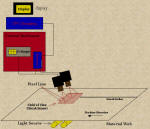

Roll Preparation |

Roll Unwind |

FCS Sheeter-wis Inspection Station |

Inspection Lighting and Optimization |

Slitting Station Input |

|

|

|

|

|

|

|

Slitting Station |

Cutting Knife Station |

Diverter Station |

Defect Reject Bin |

Layboy (good product) |

|

|

|

|

Sheet Stacking Station |

Stacked Product |

Call SDS:

Call us today to discuss your complete machine vision imaging application and to learn more about the industry's most diverse line of machine vision web inspection, hole detection, splice detection and control products.

Home | Products | Download Center | History | News | Employment | Contact | Links | Feedback | Corporate Values

Information provided herein protected - © Copyright 2003-2019 Splice Detector Systems

![]()

![]()

Production efficiency standards that facilitate

continuous quality control initiatives and machine runnability are

essential key components to ensure a competitive edge in this very

demanding segment of the market. The OPTOMIZER® FCS

Sheeter Inspection™ Technology

will provide comprehensive quality management to ensure defective

material is detected and classified diverting one or any number of

successive defective sheets prior to stacking.

Production efficiency standards that facilitate

continuous quality control initiatives and machine runnability are

essential key components to ensure a competitive edge in this very

demanding segment of the market. The OPTOMIZER® FCS

Sheeter Inspection™ Technology

will provide comprehensive quality management to ensure defective

material is detected and classified diverting one or any number of

successive defective sheets prior to stacking.

Detect and Index All

Defects:

Detect and Index All

Defects: