|

|

|

TECHNICAL SPECIFICATIONS |

|

Registration Accuracy: |

1/16"

(1.5 mm) or Less

From Registration Mark |

|

Marks

Detected: |

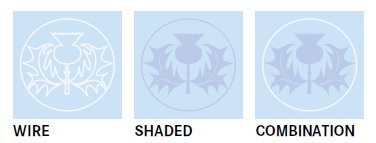

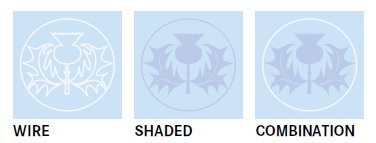

Non-Keyed Watermarks

Keyed Watermarks

Printed Watermarks

Other Marks Subject to Tests |

|

Maximum

Web Speed: |

Depending on Application |

|

Dimensions: |

Rack

Mounted |

|

Material Color Range: |

Subject

to Tests |

|

Material Color Range: |

Subject

to Tests |

|

Illumination: |

Proprietary |

|

Ambient

Temperature: |

40 to

160° F (4 to 70° C) |

|

Power:

|

110/220/240 VAC

50/60 Hz

Single Phase |

|

Specifications are subject to change without notice.

Note:

The Register Control System supplies all necessary

electronics and controls with the exception of the

double differential in the drive of the rotary

knife. The double differential is supplied by the

cutter manufacturer. |

Insure Material

Registration: Insure Material

Registration:

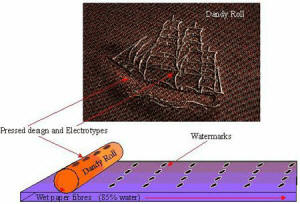

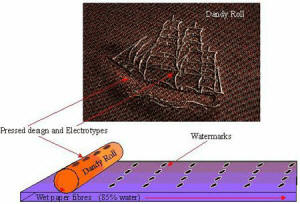

The Dandy Roll Control™

Technology

automatically controls the application of all types of

watermark, bug mark and security marks to ensure consistent

application of such marks prior to further processing.

Through system integration with production equipment, THE Dandy Roll Control™ Technology is adapted to specialized applications to ensure in-register processing of web materials. It is

suitable for many types of watermark processing in writing, text, cover,

security and private authorization registration or similar process controls.

Detect Any Mark: Detect Any Mark:

Since register mark

variations are inevitable due to temperature, humidity, web expansion

and contraction, it is very

important to implement a proportional

closed loop methodology as constant dandy roll speed cannot compensate

for mark spacing. Our proprietary drive control circuitry enables

us to control the rotational speed of the dandy roll. This

determines the linear spacing of the watermark and/or bug marks along

the web at the wet end of the machine in comparison to the measured mark

spacing at the take up end. Upon detection of the in-register

marks, their spacing is measured, displayed and compared to an operator

adjustable set point. If there is any variations an error signal

is generated and inputted into the closed loop methodology for feedback

signal response to close the control loop upon application.

The SLC module

(sheet length control) must function with a large transport

delay due to the time required for the web material to travel

the length of the machine. This could be 30 seconds at a

machine speed of 900 fpm (xxx m/min). This delay is the

time differential when the feedback signal response is applied

to the dandy roll drive controls and its affect is monitored by

the take up sensor.

For example, a machine

operating at 900 fpm (xxx m/min) travels 180 inches per second

(00cm/second) and has a mark placement every 72 inches (00cm)

thus generating a 400 millisecond mark spacing.

Theoretically, a new measurement, reading and correction can be

provided every 400 milliseconds. However, this is not

necessary nor desirable since the transport delay is 30 seconds.

Temperature, humidity or other environmental conditions causing

the in-register mark error at the take up sensor station occur

very gradually over a relatively long period of time, 30 minutes

or so. Therefore by slowing the process error anomalies

down to several transport delays, the drive controls will have

sufficient time with minimal stress to catch up and reduce the

error to zero (measurement equaling the set point). By

implementing this type of methodology, our register control technology is compatible with a wide

range of illumination, sensing, and signal processing technologies for detection of any

type of mark including keyed and none-keyed marks. The SLC module

(sheet length control) must function with a large transport

delay due to the time required for the web material to travel

the length of the machine. This could be 30 seconds at a

machine speed of 900 fpm (xxx m/min). This delay is the

time differential when the feedback signal response is applied

to the dandy roll drive controls and its affect is monitored by

the take up sensor.

For example, a machine

operating at 900 fpm (xxx m/min) travels 180 inches per second

(00cm/second) and has a mark placement every 72 inches (00cm)

thus generating a 400 millisecond mark spacing.

Theoretically, a new measurement, reading and correction can be

provided every 400 milliseconds. However, this is not

necessary nor desirable since the transport delay is 30 seconds.

Temperature, humidity or other environmental conditions causing

the in-register mark error at the take up sensor station occur

very gradually over a relatively long period of time, 30 minutes

or so. Therefore by slowing the process error anomalies

down to several transport delays, the drive controls will have

sufficient time with minimal stress to catch up and reduce the

error to zero (measurement equaling the set point). By

implementing this type of methodology, our register control technology is compatible with a wide

range of illumination, sensing, and signal processing technologies for detection of any

type of mark including keyed and none-keyed marks.

Improve Delivered Quality: Improve Delivered Quality:

The

Dandy Roll Control™ Technology can help your company improve product quality

by automatically controlling material registration within customer specifications. Choose

our Dandy Roll Control™ Technology for faster, more reliable, control of the

delivered quality of your products.

Reduce Costs:

Our

Dandy Roll Control™ Technology will help you

to significantly reduce your company's

costs for producing, sorting, and disposing of mis-registered products. They can also help

to reduce costs for machine downtime and customer returns.

Achieve High Speed Operation:

A pulse generator, combined with our illumination, sensing, and signal processing

technologies, ensures that registration accuracy is maintained throughout the process at

any process speed. Since the pulse generator is integrated with a

machine driven shaft,

registration accuracy is not speed dependent.

Call SDS:

Call us

today

to discuss your

register control application and to learn more about the

industry's most complete line of web inspection related products.

[

TOP PAGE ]

|

Insure Material

Registration:

Insure Material

Registration: Detect Any Mark:

Detect Any Mark: The SLC module

(sheet length control) must function with a large transport

delay due to the time required for the web material to travel

the length of the machine. This could be 30 seconds at a

machine speed of 900 fpm (xxx m/min). This delay is the

time differential when the feedback signal response is applied

to the dandy roll drive controls and its affect is monitored by

the take up sensor.

The SLC module

(sheet length control) must function with a large transport

delay due to the time required for the web material to travel

the length of the machine. This could be 30 seconds at a

machine speed of 900 fpm (xxx m/min). This delay is the

time differential when the feedback signal response is applied

to the dandy roll drive controls and its affect is monitored by

the take up sensor.  Improve Delivered Quality:

Improve Delivered Quality: