|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

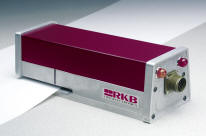

CLASSIC® SPLICE DETECTOR™

TECHNOLOGY

Technology for Innovators, fix the problem!

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Prevent downtime and reduce costly repairs to rolls, dies, and delicate production equipment used in web based material manufacturing processes with our state-of-the-art; center mount splice detection technology. This capacitance based Splice Detector (Joint Detector) reveals abrupt changes in web material thickness due to splices, missing plies and web breaks in high speed paper, coating and conversion processes.

Designed for center of web mounting, Our Splice Detector (Joint Detector) eliminates the need for repositioning to accommodate changes in web width. It can be installed at any convenient position in the web's path to provide defect detection at the earliest possible stage of the process. Both a signal contact closure and a signal digital pulse output are integrated with each detector for control or activation of peripheral equipment such as audio/visual alarms, counters, sorters, coating head applicators, corona treaters, spray marking systems and reject gate controls. With thousands of installations in over 100 countries worldwide, our splice detection (Joint Detector) technologies have been effectively established to ensure delivered product superiority on tens of thousands of materials, coated and non-coated such as papers, films, nonwovens, textiles, and tapes.

Monitor Multiple Webs: This Splice Detector (Joint Detector) can monitor multiple webs of material at one time up to a maximum of 16 webs or a total thickness of 0.20" (5.08mm) for on-line, 24/7 operation. No adjustments or calibration are required when the number of webs, type of webs, basis weight, coat weight, color and process manufacturing speeds is changed. Our Splice Detector (Joint Detector) automatically "Adjusts Itself" to new conditions or events. Special splicing tapes, colors or identification tags are not required and the operation is unaffected by printed material.

Expect Reliability: With thousands of installations in over 130 countries worldwide, our splice detection (Joint Detector) technologies have been effectively established to ensure delivered product superiority on tens of thousands of materials, coated and non-coated such as papers, films, nonwovens, textiles, and tapes. Our splice detection technologies are installed on many types of machinery including sheeters, on and off machine coaters, extrusion laminators, supercalenders, rotogravure and flexographic printing presses, holographic processes, textile and nonwoven machinery. Low speed to high speed, our Splice Detectors are proven time and time again to be the leader in performance, reliability and price.

Plug and Play: Our splice detector technology is compact, easy to install and plug and play. They can be installed in any application where the need for splice, missing ply or web break detection is required. Contained in a housing 6.0" x 7.5" x 4.37" (15.24cm x 19.05cm x 11.10cm), it can be powered by 120 or 240 VAC, 50/60 Hz, Single Phase. Operating temperatures up to 85°C. Whatever your mechanical correction, quality initiatives or control may be, our splice detector technology provides lightning fast recognition and triggering to get the job done right the first time!

Call SDS: Call us today to discuss your web inspection application and to learn more about the industry's most diverse line of machine vision web inspection, hole detection, splice detection and control products.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Home | Products | Download Center | History | News | Employment | Contact | Links | Feedback | Corporate Values |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Information provided herein protected - © Copyright 2003-2019 Splice Detector Systems

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Prevent Costly Repair:

Prevent Costly Repair: Limit Setup Time:

Limit Setup Time: