|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

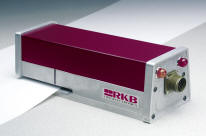

CLASSIC® SPLICE DETECTOR™

TECHNOLOGY

Technology for Innovators, fix the problem!

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Cut downtime while preventing costly repairs to rolls, dies, and delicate production equipment used in web based material manufacturing and conversion processes with our Classic® Splice Detector™ Technology. Since this state-of-the-art splice detector treats the web material as a dielectric, immediate changes in material thickness due to splices (joints), tearouts, missing plies and web breaks in non-metallic material and conversion processes are instantly revealed. Installed along any convenient point in your web, our Classic® Splice Detector™ Technology will alert production personnel at the earliest possible stage of your process (e.g., between the input roll and slitter bar).

With over 5000 installations worldwide, our splice detection technologies have been effectively applied to ensure delivered product quality on tens of thousands of materials, coated and non-coated such as papers, films, nonwovens, textiles, and tapes. Our Classic® Splice Detector™ Technology can be installed on many types of machinery including sheeters, on and off machine coaters, extrusion laminators, supercalenders, rotogravure and flexographic printing presses, holographic processes, textile and nonwoven machinery.

Both a signal contact closure and a signal digital pulse output are integrated with each splice detector for control or activation of peripheral equipment such as audio/visual alarms, counters, sorters, coating head applicators, corona treaters, spray marking systems and reject gate controls. The Classic® Splice Detector™ Technology comes as a complete package measuring 4.5" x 4.5" x 12" (11.43cm x 11.43cm x 30.48cm) and has universal mounting holes in the base and the back. All our splice detection technologies can be combined with our own Multicolor Edge marking technology for completely unattended operation of your production equipment.

Respond to Varying Conditions: Our Classic® Splice Detector™ Technology is self calibrating and can monitor single to multiple webs of material simultaneously. No adjustments, settings or re-calibrations are required and our technology is completely unaffected by basis weight changes, coat weight changes, color and process manufacturing speeds. Our Classic® Splice Detector™ Technology automatically "Adjust Themselves" for up-to-the-minute process conditions. Special splicing tapes, colors or identification tags are not required and the operation is unaffected by printed material.

Demand Proven Performance:Our Classic® Splice Detector™ Technology is designed for reliable, stable and consistent operation 24/7 in real world conditions. Designed to operate on 120/220/240 VAC, 50/60Hz, low speed through high speed coating, laminating, printing, packaging and specialized converting processes our splice detectors are proven the leader in performance, reliability and price. Installations in over 130 Countries worldwide, join with leading manufacturers who demand proven performance for their quality control initiatives.

Call SDS:Call us today to discuss your web inspection application and to learn more about the industry's most diverse line of machine vision web inspection, hole detection, splice detection and control products.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Home | Products | Download Center | History | News | Employment | Contact | Links | Feedback | Corporate Values |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Information provided herein protected - © Copyright 2003-2019 Splice Detector Systems

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Guarantee Product Quality:

Guarantee Product Quality: Minimize

Operator Intervention:

Minimize

Operator Intervention: